The Definitive Guide to Choosing an Elite Gummy Supplement Manufacturer in 2026

This comprehensive skyscraper guide assists brands in selecting an elite gummy supplement manufacturer. It covers the critical shift from traditional manufacturing to Contract Development and Manufacturing Organizations (CDMOs), detailing the benefits of end-to-end R&D, formulation, and stability testing. The article explains the technical nuances of pectin vs. gelatin, the importance of water activity and pH control, and the necessity of FDA and GMP compliance. Leveraging CSK Biotech's extensive experience since 2008, it highlights the advantages of partnering with a supplier that offers massive scalability, free packaging services, and market-ready innovation.

Introduction: The Booming Gummy Supplement Market & Why Manufacturers Matter

The global nutraceutical landscape is undergoing a seismic shift, with gummy vitamin contract manufacturing moving from a niche service to a dominant industry force. According to market research by MarketsandMarkets, the global gummy supplements market is projected to surge from approximately $24.39 billion in 2025 to nearly $47.79 billion by 2030. This explosive growth is driven by 'pill fatigue' and a consumer demand for palatable, convenient nutrition. However, capitalizing on this trend requires more than just a great idea; it demands a strategic partnership with a manufacturer capable of navigating complex formulation challenges and regulatory landscapes.

In this high-stakes environment, the choice of partner is critical. Brands can no longer rely on simple production lines; they need the sophisticated capabilities of a Contract Development and Manufacturing Organization (CDMO). CSK Biotech, a leader in this space since 2008, exemplifies this evolution. With a GMP certified facility and a commitment to end-to-end product lifecycle support, CSK Biotech moves beyond basic nutritional gummy production to offer true market differentiation for global brands.

Understanding the Gummy Manufacturing Process: From Concept to Consumer

Creating a shelf-stable, efficacious gummy is a scientifically rigorous process. High-quality custom gummy manufacturing involves a delicate balance of chemistry and engineering.

Ingredient Selection & Formulation

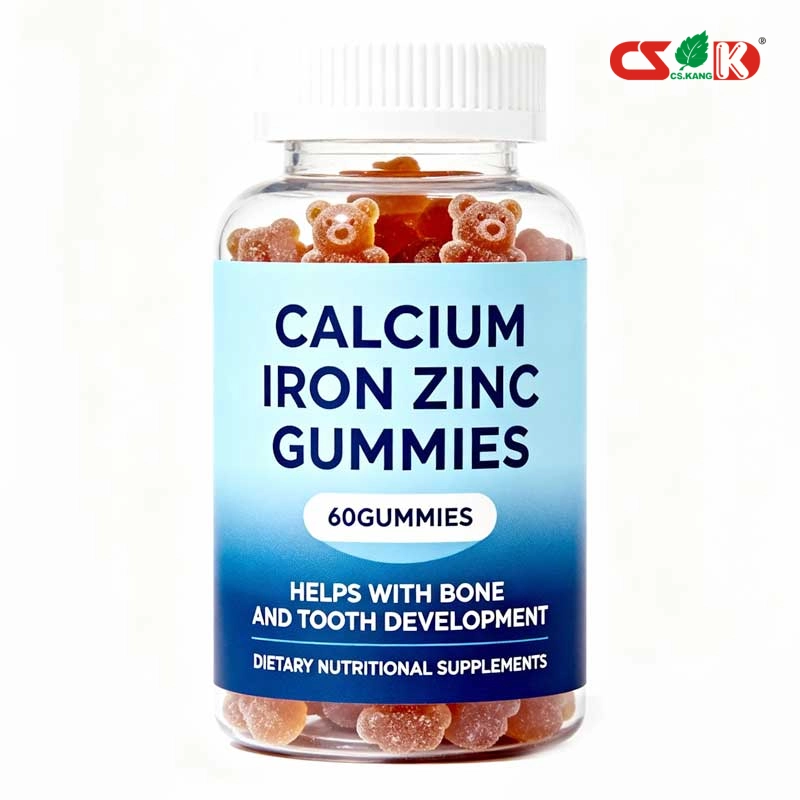

The foundation of any premium gummy is the gelling agent. While traditional gelatin (derived from collagen) provides the classic chewy texture, modern demand often shifts towards vegan gummy production using pectin or agar-agar. Pectin, derived from fruit peels, requires precise acidity (pH) and sugar concentrations to set correctly, offering a cleaner bite and better heat resistance during shipping. Gummy formulation development is one of CSK Biotech’s core strengths; our R&D team ensures optimal synergy between these agents and active ingredients like vitamins, minerals, or botanicals.

Preparation, Cooking & Homogenization

This stage involves weighing and blending ingredients with exacting precision. The mixture is cooked to a specific slurry consistency. Proper homogenization is vital to ensure that every single gummy contains the exact dosage of active ingredients claimed on the label—a common failure point for lesser manufacturers.

Molding, Cooling & Demolding

Advanced health gummy manufacturing utilizes automated deposition into Teflon-coated molds. Cooling tunnels must be strictly controlled for humidity and temperature to ensure structural integrity.

Coating & Polishing

To prevent stickiness—a notorious issue in gummy production—gummies are coated with oils or waxes (like carnauba wax) or sanded with sugar/citric acid. This step also enhances visual appeal and shelf life.

Quality Control & Packaging

From in-process checks to final packaging, quality assurance is paramount. Uniquely, CSK Biotech offers free packaging services, reducing logistical headaches for our partners and ensuring products are retail-ready immediately upon completion.

Critical Factors for High-Quality Gummy Production: Beyond the Basics

To ensure safety and efficacy, elite manufacturers monitor several non-negotiable technical parameters.

· Water Activity (Aw): This is the most critical safety metric. According to technical standards referenced in the American Pharmaceutical Review, maintaining an Aw below 0.60 is essential to prevent microbial growth in pharmaceutical gummies. While food regulations often cite 0.85 as a safety limit, high-quality supplements target lower ranges for extended stability.

· pH Levels & Acidity: Critical for gelling. Pectin, for instance, requires a narrow pH range (typically 3.2–3.6) to gel properly. Incorrect pH can lead to 'weeping' (syneresis) or failure to set.

· Temperature Control: Excessive heat can degrade sensitive vitamins (like Vitamin C) and probiotics. Advanced production lines use precise thermal regulation to preserve potency.

· Equipment & Technology: Efficiency equals consistency. CSK Biotech operates seven advanced production lines within a 2,000 m² factory, utilizing cutting-edge dosing and mixing technology to guarantee batch-to-batch uniformity.

Navigating Certifications & Regulatory Compliance: A Manufacturer's Mandate

In the supplement industry, trust is the currency of success. A GMP certified gummy manufacturer is not just a preference; it is a necessity for legal market entry.

· GMP/cGMP (Good Manufacturing Practices): Adherence to GMP ensures products are consistently produced and controlled according to quality standards. As outlined in FDA regulations (21 CFR Part 111), this covers everything from hygiene to record-keeping.

· FDA Compliance: For brands targeting the U.S., the manufacturer must comply with strict FDA guidelines for dietary supplements.

· ISO Standards: International Organization for Standardization (ISO) certification demonstrates a commitment to global quality management systems.

· HACCP: Hazard Analysis and Critical Control Points protocols prevent safety hazards in food production.

CSK Biotech holds GMPC, FDA, HACCP, and ISO certifications. This comprehensive compliance portfolio allows our partners to market their products globally with confidence, knowing they meet the highest international safety standards.

Choosing Your Strategic Partner: What Makes an Elite Gummy Supplement Manufacturer?

When evaluating potential partners, look for CDMO gummy solutions that offer scale and versatility.

1. Experience & Expertise: You need a partner who has seen it all. Founded in 2008, CSK Biotech brings over 15 years of industry data and problem-solving experience to the table.

2. Production Capacity & Scalability: Can your manufacturer grow with you? With an annual capacity exceeding 4.5 billion softgels and 1.5 billion tablets, CSK Biotech possesses the industrial infrastructure to handle massive gummy orders without bottlenecks.

3. End-to-End Solutions (CDMO Advantage): Unlike simple contract manufacturers, a CDMO supports you from the drawing board to the shelf. This includes pilot testing, stability verification, and regulatory registration support.

4. Innovation & Customization: Whether you need private label gummy supplements or a completely new invention, the ability to create unique shapes, flavors, and active combinations is key.

5. Transparent Communication: A partner should act as an extension of your team, offering clear timelines and honest feasibility assessments.

CSK Biotech: Your Trusted Contract Development and Manufacturing Organization (CDMO) for Gummy Supplements

At CSK Biotech, we redefine the manufacturing relationship. We are not just a factory; we are an innovation hub.

· Comprehensive Service Offerings: We provide flexible cooperation models including OEM (formula-based production), CDM (tailor-made design), and ODM (market-oriented product innovation). This flexibility allows us to serve both emerging startups and established global giants.

· Unmatched Facilities: Our GMP-certified 2,000 m² factory is equipped with state-of-the-art technology, ensuring that your Gummy supplement market trends strategies are backed by reliable execution.

· Value-Added Services: Beyond production, we offer professional R&D, formulation research, and our signature free packaging services.

· Commitment to Quality: Our rigorous adherence to GMPC, FDA, HACCP, and ISO standards ensures that every bottle leaving our facility is safe, effective, and compliant.

Future Trends in Gummy Supplement Manufacturing

The future of health gummy manufacturing lies in precision and personalization. We are seeing a surge in demand for:

· Personalized Nutrition: Small-batch capabilities for tailored vitamin stacks.

· New Actives: Incorporation of adaptogens, nootropics, and probiotics which require advanced encapsulation technologies to remain stable in a gummy matrix.

· Sustainability: Eco-friendly packaging and plant-based ingredients.

As a forward-thinking CDMO, CSK Biotech is actively investing in these technologies to keep our partners ahead of the curve.

Conclusion: Partnering for a Sweet Future in Supplements

The gummy supplement market offers unparalleled opportunities for growth, but only for those who prioritize quality and scalability. Choosing an elite manufacturer is the single most important decision a brand owner will make. With a legacy of excellence since 2008, massive production capacity, and a full suite of CDMO services, CSK Biotech is ready to be that partner.

Whether you need custom gummy manufacturing or a turnkey private label solution, contact us today to start building the future of health.

Frequently Asked Questions

What is a gummy supplement manufacturer?

A gummy supplement manufacturer is a specialized facility that produces dietary supplements in chewable, gelatin, or pectin-based forms. Unlike standard food candy factories, these facilities must adhere to strict pharmaceutical-grade GMP standards to ensure the stability and potency of active ingredients like vitamins and minerals.

What are the key ingredients used in gummy supplement manufacturing?

The core ingredients include gelling agents (gelatin, pectin, or agar-agar), sweeteners (sucrose, glucose syrup, or sugar-free alternatives like erythritol), and active ingredients (vitamins, botanicals). Flavorings and acidulants (citric acid) are added to balance taste and control pH.

How does a CDMO differ from a traditional contract manufacturer?

A traditional contract manufacturer (CMO) typically produces a product based on a formula you provide. A CDMO (Contract Development and Manufacturing Organization), like CSK Biotech, offers comprehensive end-to-end solutions. This includes Research & Development (R&D), formulation creation, pilot testing, stability verification, and regulatory support, alongside the actual manufacturing.

What quality certifications should I look for in a gummy manufacturer?

You should strictly look for manufacturers with GMP (Good Manufacturing Practices) certification. Additionally, FDA registration (for the US market), ISO (International Organization for Standardization), and HACCP (Hazard Analysis Critical Control Point) certifications are strong indicators of a manufacturer's reliability and safety standards. CSK Biotech holds all these major certifications.

Can a gummy manufacturer produce vegan or sugar-free options?

Yes. Advanced manufacturers can produce vegan gummies using pectin or agar-agar instead of animal-based gelatin. Sugar-free options are also possible using sugar alcohols or high-intensity sweeteners. CSK Biotech specializes in these custom formulations to meet diverse consumer dietary needs.

What are the benefits of private label or contract gummy manufacturing?

Contract manufacturing allows brands to enter the market quickly without the massive capital investment required to build a factory. It grants access to expert R&D, established supply chains, and scalable production capacity, allowing the brand to focus entirely on marketing and sales.

What is the typical lead time for gummy supplement manufacturing?

Lead times vary based on whether the formula is a stock item or a custom R&D project. It also depends on raw material availability and the manufacturer's current schedule. Typically, it can range from a few weeks for standard products to several months for complex custom developments.

How does CSK Biotech support new product development for gummy supplements?

CSK Biotech supports development through its ODM and CDM cooperation models. We provide professional R&D, formulation research, and pilot testing to validate new concepts before mass production. We also assist with regulatory registration and offer free packaging design services to ensure your product is market-ready.

References

· MarketsandMarkets: Gummy Supplements Market Size, Share & Trends Analysis

· FDA: 21 CFR Part 111 - Current Good Manufacturing Practice for Dietary Supplements

· American Pharmaceutical Review: Microbiological Attributes of Chewable Gels (Gummies)

Latest Popular Articles

Discover expert tips from CSK Biotech, one of the top dietary supplements manufacturers, on handling international shipping and compliance for supplements. Ensure smooth global distribution with our comprehensive guide to regulations, packaging, and documentation. Stay compliant and competitive worldwide.

FAQ

文章

Who is CSK Biotech?

CSK Biotech is a professional biotechnology company specializing in OEM/ODM contract manufacturing of dietary supplements. We provide customized production services for softgel capsules, hard capsules, tablets, powders, gummies, and liquid supplements, supporting global brands from formulation to finished products.

Can CSK Biotech assist with labeling and documentation?

Yes. We provide support for:

-

· Product labeling requirements

-

· Ingredient lists and specifications

-

· Basic regulatory documentation

This helps ensure smoother market entry and compliance with customer requirements.

What types of dosage forms does CSK Biotech manufacture?

We offer a full range of supplement dosage forms, including:

-

· Softgel capsules

-

· Hard capsules

-

· Tablets

-

· Powder supplements

-

· Gummy supplements

-

· Liquid supplements (drops, syrups, oral liquids)

This allows our clients to build a complete and diversified product line with one reliable manufacturing partner.

What ingredients can be used in your products?

We support a wide range of ingredients, such as:

-

· Vitamins and minerals

-

· Herbal extracts

-

· Amino acids

-

· Probiotics and prebiotics

-

· Functional ingredients for immunity, beauty, sleep, energy, and metabolism

All raw materials are carefully selected and quality-tested before use.

How long does production usually take?

Production timelines vary depending on:

-

· Dosage form

-

· Formula complexity

-

· Order quantity

-

· Packaging requirements

Generally, production takes several weeks after formula confirmation and raw material preparation.

Does CSK Biotech provide OEM and ODM services?

Yes. CSK Biotech provides both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services.

-

OEM: Manufacturing based on your existing formula and specifications

-

ODM: Full product development including formulation, dosage form design, and production

Our R&D team works closely with clients to turn concepts into market-ready products.

Related Products

Explore our range of complementary dietary supplement products designed to meet diverse formulation and market needs. Each item is developed and manufactured with the same high-quality standards and expertise that define our dietary supplement contract manufacturing services, helping brands expand their product offerings efficiently and reliably.

Request a Quote for Dietary Supplement Contract Manufacturing

If you need CDMO services for health foods, nutritional supplements, or cosmetics, our team of experts is ready to provide you with customized solutions and quotes.

manufactoryinchina

CSK Biotech Dietary Supplements