Navigating the Future of Nutrition: Choosing the Best Liquid Dietary Supplement Manufacturers in 2026

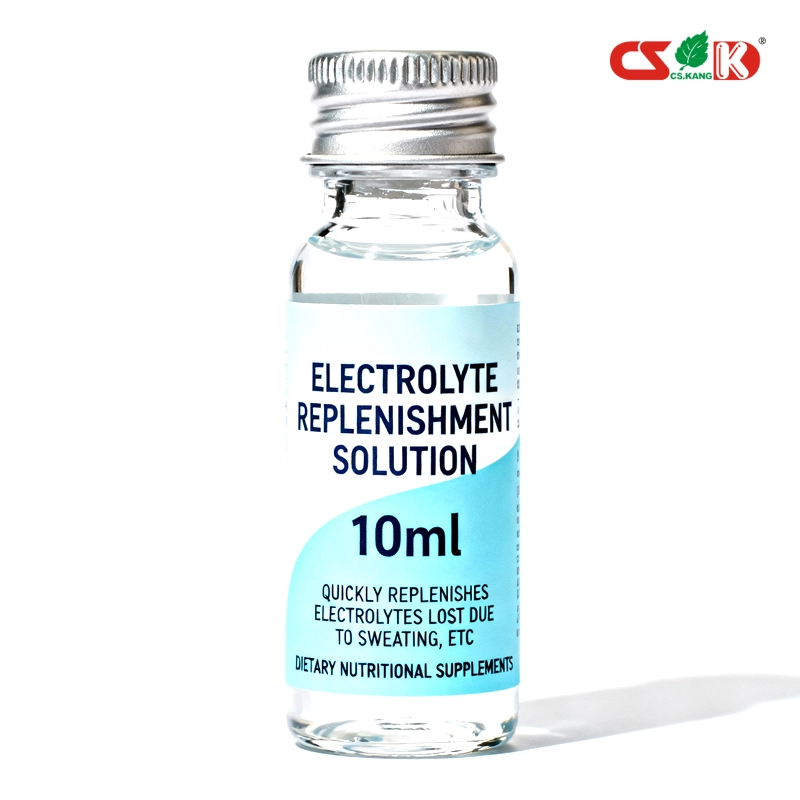

This comprehensive guide analyzes the booming liquid dietary supplement market, projected to reach USD 53.1 billion by 2033. It details how to choose the right manufacturer by understanding partnership models (OEM, ODM, CDM), the strategic value of end-to-end CDMOs, and the importance of strict quality certifications like GMP and FDA registration. The article also highlights the capabilities of industry veterans like CSK Biotech in delivering innovative liquid formulations.

As the global wellness industry evolves, the demand for more bioavailable and convenient nutritional formats has skyrocketed. The era of swallowing handfuls of large tablets is giving way to the precision and ease of liquid formulations. For brands looking to capitalize on this shift, choosing the right liquid dietary supplement manufacturers is the single most critical decision they will make in 2026.

Recent data indicates that the global liquid dietary supplements market is on a trajectory of robust growth, valued at USD 29.2 billion in 2024 and projected to surge to USD 53.1 billion by 2033, expanding at a CAGR of 6.9% (IMARC Group; Grand View Research). This growth is driven by an aging population, a rise in chronic lifestyle diseases, and a consumer pivot toward "pill fatigue" solutions. In this competitive landscape, partnering with a seasoned liquid supplement contract manufacturing expert—like CSK Biotech, a high-tech enterprise founded in 2008—can provide the technological edge and scalability required to dominate the market.

The Rise of Liquid Dietary Supplements: A Market Overview

Defining the Shift to Liquids

Liquid dietary supplements encompass a broad category of non-solid nutritional products, including vitamins, minerals, herbal extracts, and specialized nutraceuticals. Unlike traditional solid dose forms, liquids offer a versatile platform for complex formulations that are easier to ingest—a crucial factor for children and seniors.

Consumer Advantages: Absorption and Ease

The primary driver behind the popularity of liquid formats is bioavailability. Liquid delivery systems often allow for more rapid absorption of active ingredients into the bloodstream compared to compressed tablets, which must break down in the digestive tract. Furthermore, liquids allow for flexible dosing and innovative flavor profiles, enhancing compliance and user experience. As noted by TCI Bio, consumers are increasingly embracing these formats for their convenience and efficacy.

Market Trends and Innovation

The demand for nutraceutical liquid manufacturing is being fueled by trends such as personalized nutrition and functional beverages. Brands are seeking innovative formulations that combine immunity support, energy, and cognitive health into single-dose shots or drops. This shift requires manufacturers to possess advanced stability testing capabilities to ensure potent ingredients remain effective in liquid suspension.

Essential Services Offered by Leading Liquid Dietary Supplement Manufacturers

Top-tier manufacturers do more than just blend ingredients; they act as comprehensive innovation partners. Leading facilities offer a suite of services designed to take a product from a mere idea to a shelf-ready commodity.

Comprehensive R&D and Formulation Development

Access to expert supplement R&D services is vital. A competent manufacturer provides concept development, formulation research, and pilot testing. For instance, CSK Biotech leverages its role as a professional Contract Development and Manufacturing Organization (CDMO) to offer end-to-end solutions, including stability verification to ensure liquid products do not degrade over time.

Diverse Manufacturing Capabilities

Scale is a significant differentiator. High-quality manufacturing requires advanced production lines capable of handling varying viscosities and packaging types. CSK Biotech, for example, operates a GMP-certified 2,000 m² factory with seven advanced production lines. While they have a massive capacity exceeding 4.5 billion softgels and 1.5 billion tablets, their core competency extends to high-quality liquid manufacturing, ensuring scalable solutions for global brands.

Quality Control and Certifications

Adherence to international standards is non-negotiable. Reputable partners maintain certifications such as GMPC (Good Manufacturing Practice of Cosmetics/Consumer Goods), FDA registration, HACCP (Hazard Analysis Critical Control Point), and ISO. These frameworks ensure that every batch meets rigorous safety and potency standards.

Full-Service Packaging Solutions

Presentation is key in the retail environment. Manufacturers that offer free, customizable packaging services add immense value. Whether it is dropper bottles, single-serve shots, or bulk liquid containers, integrated packaging solutions streamline the supply chain.

Understanding Different Partnership Models: OEM, ODM, and CDM with Expert Manufacturers

Navigating the acronyms of manufacturing is essential for selecting the right engagement model for your business strategy.

· OEM (Original Equipment Manufacturing): In this model, the brand provides the specific formula and design, and the manufacturer executes the production. It allows for precise, formula-based production ensuring accuracy. This is ideal for established brands with their own R&D teams who need a liquid vitamin manufacturer to scale production (OpsNinja).

· ODM (Original Design Manufacturing): Here, the manufacturer provides the intellectual property, offering market-oriented product innovation. The brand selects a pre-developed formula and rebrands it. This reduces time-to-market significantly and leverages the manufacturer's expertise in flavor systems and stability.

· CDM (Contract Development and Manufacturing): This model offers a middle ground with tailor-made product design. It involves a collaborative approach to create customized solutions that may not fit strictly into OEM or ODM boxes.

Versatile partners like CSK Biotech offer all three cooperation models, providing the flexibility to switch from an ODM starter product to a fully custom CDM formulation as a brand matures.

The Strategic Advantage of an End-to-End CDMO for Liquid Supplements

What is a CDMO?

A Contract Development and Manufacturing Organization (CDMO) represents an evolution in outsourcing. Unlike a standard contract manufacturer that may only focus on production, a CDMO liquid supplements partner manages the entire product lifecycle (Medical Packaging Inc).

The End-to-End Approach

Partnering with a CDMO like CSK Biotech streamlines the supply chain. Their process covers concept development, raw material sourcing, formulation research, pilot testing, stability verification, regulatory registration, and final production. This holistic approach eliminates the need for brands to coordinate between multiple vendors for R&D, testing, and bottling.

Key Benefits: Speed and Compliance

The strategic advantages are clear: accelerated time-to-market and reduced operational complexity. By handling regulatory hurdles—such as FDA compliance and documentation—a CDMO ensures that private label liquid supplements are launch-ready without legal bottlenecks. This integrated support system is crucial for navigating the complex regulatory landscape of liquid nutraceuticals.

What to Look for When Choosing Your Liquid Dietary Supplement Manufacturer

Selecting a partner is a long-term investment. Here are the pillars of a successful partnership:

· Experience and Expertise: Longevity signals reliability. Manufacturers with a proven track record, such as CSK Biotech (founded in 2008), bring over a decade of problem-solving experience to the table.

· Advanced Facilities and Capacity: You need a partner that can grow with you. Look for facilities that boast significant square footage (e.g., 2,000 m²) and multiple production lines to handle surges in demand without bottlenecks.

· Commitment to Quality and Safety: Verify that the potential partner is a GMP certified liquid manufacturer. Certifications like FDA registration, GMPC, HACCP, and ISO are objective indicators of a manufacturer’s commitment to safety and quality assurance (Sawgrass Nutra Labs).

· Innovation and Technology: The ability to mask bitter notes in vitamins or create stable emulsions requires advanced technology. Choose partners known for strong innovation capabilities.

· Customer-Focused Approach: A manufacturer should view themselves as an extension of your team, committed to helping global brands meet consumer demands worldwide.

Ensuring Quality and Compliance in Liquid Supplement Manufacturing

In the liquid supplement sector, quality control is paramount due to the high risk of microbial contamination in aqueous environments. Strict adherence to cGMP (Current Good Manufacturing Practices) protocols is essential (Vitaquest International; PubMed Central).

Leading manufacturers implement rigorous ingredient sourcing, testing, and traceability practices. This involves comprehensive quality assurance from raw materials to the finished product, including identity testing, heavy metal analysis, and microbial screening. Furthermore, post-production support, such as stability testing and shelf-life validation, ensures the product remains safe and effective until the last drop is consumed.

Conclusion: Partnering with the Right Liquid Dietary Supplement Manufacturer for Future Success

As the market for liquid health products marches toward a $53.1 billion valuation, the choice of manufacturer will define a brand's ability to compete. Success in 2026 and beyond relies on selecting a partner that offers more than just capacity—they must offer capability.

Partnering with an experienced, certified, and innovation-driven CDMO like CSK Biotech positions a brand for sustained growth. By leveraging comprehensive services—from supplement R&D services to private label liquid supplements production—brands can deliver high-quality, safe, and effective products that meet the sophisticated demands of modern consumers.

FAQ

What are the primary benefits of liquid dietary supplements over other forms?

Liquid supplements offer enhanced absorption rates and bioavailability compared to pills or capsules. They are also easier to consume for individuals who have difficulty swallowing tablets (dysphagia) and offer greater flexibility in dosage adjustment and flavor customization.

What key certifications should a reputable liquid supplement manufacturer possess?

A reputable manufacturer should hold GMP (Good Manufacturing Practices) certification to ensure product quality and safety. Additionally, FDA registration and adherence to cGMP protocols are critical. International certifications like GMPC, HACCP, and ISO further demonstrate a commitment to global quality standards.

What is the difference between OEM, ODM, and CDM services in supplement manufacturing?

OEM (Original Equipment Manufacturing) involves precise production based on a client's existing formula. ODM (Original Design Manufacturing) focuses on market-oriented innovation where the manufacturer provides the formula. CDM (Contract Development and Manufacturing) offers tailor-made design and end-to-end development, covering the entire lifecycle from concept to market.

How does an end-to-end CDMO streamline the liquid supplement manufacturing process?

An end-to-end CDMO liquid supplements partner reduces complexity by managing concept development, formulation research, pilot testing, production, regulatory registration, and marketing support. This integrated approach minimizes risks, provides a single point of contact, and significantly accelerates time-to-market.

What types of liquid dietary supplements can typically be manufactured?

Manufacturers can produce a wide range of products, including liquid vitamins, minerals, herbal extracts, essential oils (like Omega-3s), and specialized nutraceutical formulations for immunity, energy, cognition, beauty, and general wellness.

Can liquid supplement manufacturers assist with regulatory registration and compliance?

Yes, leading manufacturers often provide support for regulatory registration. They ensure formulations, manufacturing processes, and packaging comply with local and international regulations, such as FDA or health authority requirements, which is crucial for seamless market entry.

What factors influence the cost of liquid dietary supplement manufacturing?

Costs are influenced by formulation complexity, ingredient prices, batch size (MOQs), packaging requirements, and additional services like R&D. Partnering with a full-service manufacturer can often optimize costs through scalable production and integrated solutions.

How long does the liquid supplement development and manufacturing process usually take?

Timelines vary based on complexity. Simple OEM orders are generally faster, while custom CDM projects involving extensive R&D can take longer. A well-organized CDMO will provide estimated timelines and work to expedite the process without compromising quality.

References

· Liquid Dietary Supplements Market Size, Share & Growth Report, 2030

· Liquid Dietary Supplements Market Report - IMARC Group

· Dietary Supplements: A Framework for Quality Assurance - PubMed Central (PMC)

Latest Popular Articles

Discover expert tips from CSK Biotech, one of the top dietary supplements manufacturers, on handling international shipping and compliance for supplements. Ensure smooth global distribution with our comprehensive guide to regulations, packaging, and documentation. Stay compliant and competitive worldwide.

FAQ

文章

What is your minimum order quantity (MOQ)?

MOQ depends on the dosage form, formula complexity, and packaging requirements. CSK Biotech offers flexible MOQs to support:

-

· Start-up brands

-

· New product launches

-

· Large-scale production orders

Please contact us for specific MOQ details.

What ingredients can be used in your products?

We support a wide range of ingredients, such as:

-

· Vitamins and minerals

-

· Herbal extracts

-

· Amino acids

-

· Probiotics and prebiotics

-

· Functional ingredients for immunity, beauty, sleep, energy, and metabolism

All raw materials are carefully selected and quality-tested before use.

Does CSK Biotech provide OEM and ODM services?

Yes. CSK Biotech provides both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services.

-

OEM: Manufacturing based on your existing formula and specifications

-

ODM: Full product development including formulation, dosage form design, and production

Our R&D team works closely with clients to turn concepts into market-ready products.

Can you help with gummy supplement customization?

Yes. Custom gummy supplements are one of our core strengths. We offer:

-

· Gelatin or pectin-based gummies

-

· Sugar-free or low-sugar options

-

· Customized flavors, colors, shapes, and textures

Our gummies are developed with a focus on taste, stability, and consumer appeal.

Can CSK Biotech customize formulations?

Absolutely. We offer full formulation customization, including:

-

· Active ingredients selection

-

· Dosage optimization

-

· Flavor and taste adjustment

-

· Stability and bioavailability improvement

Our technical team ensures that each formula is safe, effective, and suitable for the target market.

Are your manufacturing facilities GMP certified?

Yes. CSK Biotech operates under GMP (Good Manufacturing Practices) standards. Our production facilities follow strict quality · · · management systems to ensure:

-

· Product safety

-

· Batch consistency

-

· Full traceability of raw materials and finished products

Related Products

Explore our range of complementary dietary supplement products designed to meet diverse formulation and market needs. Each item is developed and manufactured with the same high-quality standards and expertise that define our dietary supplement contract manufacturing services, helping brands expand their product offerings efficiently and reliably.

Request a Quote for Dietary Supplement Contract Manufacturing

If you need CDMO services for health foods, nutritional supplements, or cosmetics, our team of experts is ready to provide you with customized solutions and quotes.

manufactoryinchina

CSK Biotech Dietary Supplements