Health Supplement Manufacturer: The Definitive 2026 Blueprint for Quality & Growth

A comprehensive 2026 blueprint for brand owners on selecting the right health supplement manufacturer. This guide covers regulatory compliance (FDA, GMP), quality control standards, the differences between private label and custom formulation, and strategies for building a scalable, future-proof partnership in the booming nutraceutical industry.

Introduction: Navigating the Complex World of Health Supplement Manufacturing

The global health and wellness market is experiencing unprecedented growth. According to reports by Grand View Research, the global nutritional supplements market size was valued at nearly $485 billion in 2024 and is projected to expand significantly by 2030. For brand owners, this presents a lucrative opportunity, but it also introduces a labyrinth of challenges—chief among them is selecting a manufacturing partner who can deliver consistent quality, safety, and scalability.

Choosing a contract supplement manufacturing partner is arguably the single most critical decision you will make. It determines not just your product's quality, but your brand's reputation and legal standing. In an industry where trust is paramount, a single quality control failure can be catastrophic. This comprehensive blueprint is designed to guide you through the complexities of choosing a nutraceutical manufacturer in 2026, moving beyond basic checklists to provide actionable frameworks for a successful, long-term partnership.

Understanding the Health Supplement Manufacturing Landscape

Before diving into selection criteria, it is essential to distinguish between the primary business models in the industry. Misunderstanding these terms often leads to misaligned expectations regarding costs, timelines, and intellectual property.

Types of Manufacturers

· Contract Manufacturers: This model involves creating a unique custom supplement formulation service. You, the brand owner, typically own the formula (or license it exclusivity), and the manufacturer produces it to your exact specifications. This offers maximum differentiation but requires higher Minimum Order Quantities (MOQs) and longer lead times (typically 12–16 weeks).

· Private Label / White Label Manufacturers: Often used interchangeably, private label supplement manufacturer and white label supplement production refer to buying pre-existing formulas that the manufacturer already produces. As noted by industry experts at Vitaquest, this is a "plug-and-play" model with lower MOQs and faster turnaround times, but it offers limited opportunities for unique product differentiation.

Key Industry Segments

The manufacturing landscape is further divided by specialization. Some facilities focus exclusively on powders and capsules, while others specialize in "functional foods" like gummies or liquids. Understanding these capabilities is vital when aligning with health supplement industry trends toward novel delivery systems.

The Journey from Concept to Consumer: A Step-by-Step Manufacturing Process

A transparent dietary supplement production process is the hallmark of a reliable partner. The journey involves several critical stages:

1. Product Conceptualization: Defining the target audience and unique selling proposition.

2. Formulation Development: Balancing efficacy with manufacturability. This stage often involves R&D teams refining the "flow" of powders or the stability of liquids.

3. Raw Material Sourcing: Procuring ingredients that meet strict identity and purity standards.

4. Manufacturing & Production: The physical blending, encapsulation, or compression of the product.

5. Quality Control & Assurance: Rigorous testing at multiple stages (receiving, in-process, finished goods).

6. Regulatory Approval: Ensuring labels meet FDA compliant supplement manufacturing guidelines.

Non-Negotiables: Regulatory Compliance and Certifications

In the United States, the Food and Drug Administration (FDA) regulates finished dietary supplements under 21 CFR Part 111. These are the Current Good Manufacturing Practices (cGMPs) specifically for dietary supplements.

Deep Dive into GMP and FDA Compliance

Compliance is not optional. GMP certified health supplements are those produced in facilities that strictly adhere to these federal regulations. According to the FDA, 21 CFR Part 111 requires manufacturers to establish specifications for the identity, purity, strength, and composition of every dietary ingredient and finished product. A common pitfall for brands is assuming a manufacturer is compliant simply because they say so. You must verify their audit history.

Third-Party Certifications: The Gold Standard

While the FDA inspects facilities, they do not "certify" them in the commercial sense. Therefore, authoritative brands look for third-party validations. As highlighted by NSF International, independent certification involves regular on-site audits and product testing to verify that what is on the label is in the bottle. Key certifications to look for include:

· NSF International (GMP Registration & Certified for Sport)

· USP (United States Pharmacopeia)

· ISO 9001 / ISO 17025 (for laboratory competence)

· Organic, Non-GMO Project, Halal, and Kosher (depending on your market)

Quality Control Excellence: Beyond Standard Testing

To ensure supplement quality control standards, a manufacturer must utilize advanced analytical testing. It is insufficient to rely solely on a supplier's Certificate of Analysis (CoA).

Comprehensive Testing Protocols

According to NaturPro Scientific, robust quality control involves:

· Identity Testing: Using HPTLC (High-Performance Thin-Layer Chromatography) or FTIR (Fourier Transform Infrared Spectroscopy) to confirm the botanical or chemical identity of an ingredient.

· Potency Testing: Using HPLC (High-Performance Liquid Chromatography) to verify the concentration of active compounds.

· Contaminant Testing: Using ICP-MS (Inductively Coupled Plasma Mass Spectrometry) for heavy metals and GC-MS (Gas Chromatography-Mass Spectrometry) for pesticides and residual solvents.

A strong Quality Management System (QMS) will document these tests for every single batch, ensuring traceability from the farm to the finished capsule.

Ingredient Sourcing & Supply Chain Mastery

Transparency is the antidote to adulteration. The best manufacturers maintain a vetted network of raw material suppliers. They should be able to answer: "Where does this Ashwagandha come from?" and "How do we know it isn't diluted with filler?"

Ethical sourcing is also becoming a consumer priority. As reported by Grand View Research, the rise in demand for plant-based and sustainable products is reshaping supply chains. Manufacturers must now prove not just the purity of their ingredients, but the integrity of their origins.

Key Considerations When Selecting Your Ideal Manufacturing Partner

When choosing a nutraceutical manufacturer, evaluate them against these strategic pillars:

· Experience & Track Record: Do they have a history of FDA warning letters, or are their audit reports clean?

· Production Capacity: Can they scale from 5,000 bottles to 500,000 without compromising lead times?

· Turnaround Time: Standard lead times are 8–12 weeks for re-orders, but raw material shortages can extend this. Ask about their inventory strategy.

· Pricing Structure: Be wary of quotes that seem too good to be true. Low prices often hide cut corners in testing or lower-grade raw materials.

· IP Protection: Ensure your custom formulations are protected by a solid Non-Disclosure Agreement (NDA) and Manufacturing Agreement.

Building a Lasting Partnership: Beyond the Contract

The relationship between a brand and its manufacturer should be symbiotic. Effective communication is the cornerstone of this partnership. Regular progress reviews and open access to production teams can prevent minor issues from becoming major delays.

Furthermore, utilize your manufacturer's R&D expertise. A proactive partner will suggest formulation optimizations to improve stability or lower costs without sacrificing quality. As you scale, discuss "blanket orders" or supply agreements to lock in pricing and capacity for the year ahead.

Future-Proofing Your Supplement Brand: Innovation in 2026

The industry is moving fast. By 2026, health supplement industry trends will be dominated by precision and personalization.

· AI in Quality Control: Advanced manufacturers are beginning to use Artificial Intelligence to predict supply chain disruptions and optimize blending processes for better homogeneity.

· Personalized Nutrition: Manufacturers are adapting to "batch size one" or micro-batching to support brands offering DNA-based custom vitamin packs.

· Sustainability: Expect a shift toward biodegradable packaging and energy-efficient manufacturing processes as regulatory pressure and consumer demand for "green" products intensify.

Conclusion: Your Path to a High-Quality, Market-Leading Supplement Brand

Selecting the right partner is a rigorous process that requires due diligence, regulatory knowledge, and strategic foresight. By prioritizing GMP certified health supplements and demanding transparency in the dietary supplement production process, you protect your consumers and future-proof your business. Whether you opt for a private label supplement manufacturer for speed or a contract manufacturer for innovation, remember that your manufacturer is the engine room of your brand. Choose one that is built for the standards of 2026 and beyond.

Frequently Asked Questions

What is the difference between a contract manufacturer and a private label manufacturer?

A contract manufacturer produces a custom formula developed specifically for your brand, offering full control over ingredients and dosage. A private label supplement manufacturer provides pre-formulated, ready-to-sell products that you brand as your own, which is faster but offers less differentiation.

What are GMP certifications and why are they crucial?

GMP (Good Manufacturing Practices) certifications verify that a facility meets the FDA's strict safety and quality standards (21 CFR Part 111). They are crucial because they ensure the product is consistently produced and controlled, minimizing risks involved in pharmaceutical production.

How important is ingredient sourcing transparency?

It is vital. Transparency ensures that ingredients are authentic, potent, and free from contaminants. It also protects your brand from supply chain scandals and allows you to verify claims like "organic" or "sustainably sourced."

What should I consider regarding Minimum Order Quantity (MOQ)?

MOQ determines your initial capital outlay. Low MOQs (e.g., 500 units) are common in white label supplement production and are good for testing markets. Custom formulations typically require higher MOQs (e.g., 1,500–5,000 units) to make the manufacturing run efficient.

How can I assess a manufacturer's quality control processes?

Ask to see their SOPs (Standard Operating Procedures) for testing. Request a tour of their lab (virtual or physical) and ask for examples of batch records and Certificates of Analysis (CoAs) from third-party labs. Look for certifications from NSF or USP.

What role does R&D play in a manufacturing partnership?

A strong R&D team helps you innovate by creating unique delivery systems (like gummies or stick packs), improving flavor profiles, and ensuring your formula is shelf-stable and effective.

What are common challenges when working with a manufacturer?

Common challenges include lead time delays due to ingredient shortages, communication gaps, and price fluctuations. These can be mitigated by clear contracts, regular forecasting, and choosing a partner with a robust supply chain.

How can a manufacturer help with product packaging?

Most manufacturers offer turnkey solutions that include sourcing bottles, caps, and sachets. They can also provide templates for label design to ensure your artwork fits the physical packaging and meets regulatory spacing requirements.

References

· Grand View Research: Nutritional Supplements Market Size, Share & Trends Analysis Report

Latest Popular Articles

Discover expert tips from CSK Biotech, one of the top dietary supplements manufacturers, on handling international shipping and compliance for supplements. Ensure smooth global distribution with our comprehensive guide to regulations, packaging, and documentation. Stay compliant and competitive worldwide.

FAQ

文章

What quality control measures do you have?

Our quality control system includes:

-

· Raw material inspection and verification

-

· In-process quality monitoring

-

· Finished product testing

-

· Batch record management and traceability

Quality and compliance are integrated into every stage of our manufacturing process.

What types of dosage forms does CSK Biotech manufacture?

We offer a full range of supplement dosage forms, including:

-

· Softgel capsules

-

· Hard capsules

-

· Tablets

-

· Powder supplements

-

· Gummy supplements

-

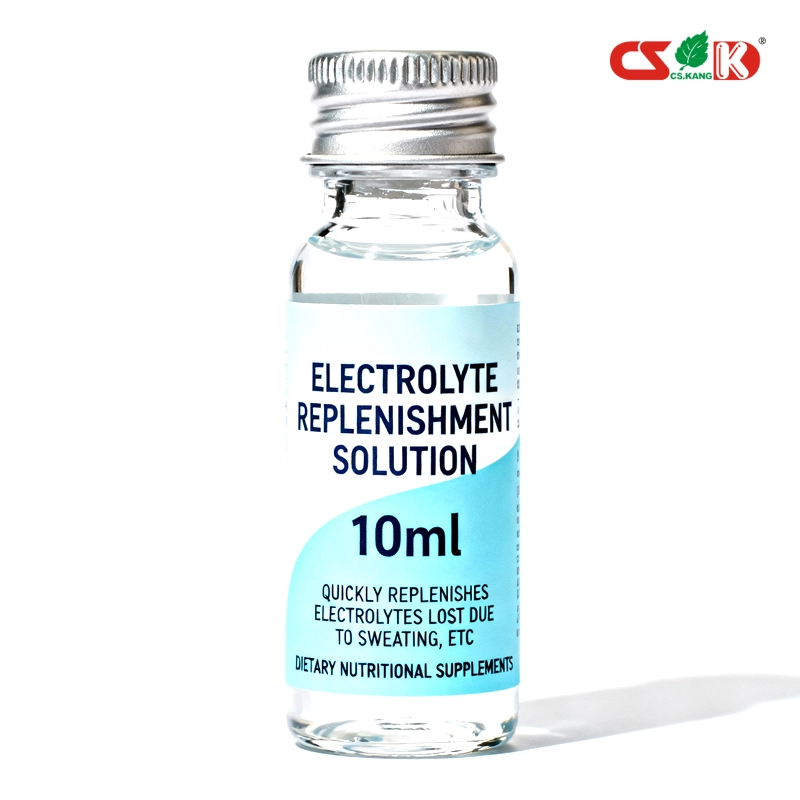

· Liquid supplements (drops, syrups, oral liquids)

This allows our clients to build a complete and diversified product line with one reliable manufacturing partner.

Can CSK Biotech assist with labeling and documentation?

Yes. We provide support for:

-

· Product labeling requirements

-

· Ingredient lists and specifications

-

· Basic regulatory documentation

This helps ensure smoother market entry and compliance with customer requirements.

Do you provide packaging services?

Yes. We offer a variety of packaging solutions, including:

-

· Bottles and jars

-

· Sachets and sticks

-

· Bulk packaging

-

· Customized labeling options

Packaging can be tailored to your brand and target market needs.

How long does production usually take?

Production timelines vary depending on:

-

· Dosage form

-

· Formula complexity

-

· Order quantity

-

· Packaging requirements

Generally, production takes several weeks after formula confirmation and raw material preparation.

What ingredients can be used in your products?

We support a wide range of ingredients, such as:

-

· Vitamins and minerals

-

· Herbal extracts

-

· Amino acids

-

· Probiotics and prebiotics

-

· Functional ingredients for immunity, beauty, sleep, energy, and metabolism

All raw materials are carefully selected and quality-tested before use.

Related Products

Explore our range of complementary dietary supplement products designed to meet diverse formulation and market needs. Each item is developed and manufactured with the same high-quality standards and expertise that define our dietary supplement contract manufacturing services, helping brands expand their product offerings efficiently and reliably.

Request a Quote for Dietary Supplement Contract Manufacturing

If you need CDMO services for health foods, nutritional supplements, or cosmetics, our team of experts is ready to provide you with customized solutions and quotes.

manufactoryinchina

CSK Biotech Dietary Supplements