Dietary Supplement Makers: Your Ultimate Guide to Quality, Innovation & Market Leadership in 2026

A comprehensive guide for 2026 on navigating the dietary supplement manufacturing landscape. Learn about CDMO advantages, FDA 21 CFR Part 111 compliance, and how to select the right partner for innovation and growth, featuring insights on CSK Biotech's end-to-end solutions.

Introduction: Navigating the Landscape of Dietary Supplement Makers

The global health and wellness industry is experiencing an unprecedented boom. According to market analysis by Grand View Research and P&S Intelligence, the global dietary supplement market is projected to grow significantly, moving from an estimated value of over $155 billion in 2024 to nearly $275 billion by 2030. For brand owners, this surge presents a lucrative opportunity, but seizing it requires more than just a great idea—it demands a robust partnership with elite dietary supplement makers.

In 2026, the difference between a thriving brand and a stagnant one often lies in the manufacturing partner they choose. It is no longer enough to find a factory that simply presses tablets; brands need strategic allies who understand contract supplement manufacturing inside and out. Whether you are scaling an existing product line or launching a new venture, navigating the complexities of dietary supplement regulations and production requires a partner capable of delivering excellence from concept to consumer.

Understanding the Role of Modern Dietary Supplement Makers: Beyond Production

Historically, manufacturers were silent back-end operators. Today, the landscape has shifted towards the CDMO dietary supplements model. A Contract Development and Manufacturing Organization (CDMO) differs significantly from a traditional Contract Manufacturing Organization (CMO). As defined by industry resources like Wikipedia, while a CMO focuses primarily on the act of production, a CDMO provides comprehensive services that span the entire development curve—from pre-formulation and R&D to commercial production and packaging.

This shift is vital for modern brands. A partner like CSK Biotech exemplifies this evolution. Founded in 2008, CSK Biotech has transitioned from a standard manufacturer into a high-tech enterprise offering end-to-end solutions. By integrating supplement formulation services with large-scale production, a CDMO acts as an extension of your own team, ensuring that R&D innovation is built directly into the manufacturing process.

The End-to-End Product Lifecycle with a Leading CDMO

Partnering with a full-service CDMO streamlines the supplement production process, reducing time-to-market and mitigating risk. Here is what that journey looks like with a top-tier partner:

1. Concept Development & Advanced Formulation

The process begins with transforming market insights into viable products. Supplement formulation services are critical here. Expert R&D teams assist in scientific ingredient selection, dosage optimization, and creating unique delivery systems. Whether you need health supplement manufacturing for immune support or sports performance, the formulation stage sets the foundation for efficacy.

2. Ingredient Sourcing & Vetting

Quality starts with raw materials. Ingredient sourcing supplements requires a rigorous vetting process to ensure purity, potency, and sustainability. A reputable manufacturer implements strict vendor qualification programs to prevent adulteration, a concern highlighted by regulatory bodies globally.

3. Pilot Testing & Stability Verification

Before mass production, a CDMO conducts pilot runs. This step is essential for process optimization and verifying product stability. It ensures that the bioactive compounds remain potent throughout the product's shelf life.

4. Large-Scale Production Excellence

Scalability is a non-negotiable factor for growing brands. Leading manufacturers utilize advanced facilities to meet global demand. For instance, CSK Biotech operates a GMP-certified 2,000 square meter factory equipped with seven advanced production lines. This infrastructure supports an immense annual capacity, exceeding 4.5 billion softgels and 1.5 billion tablets, ensuring that supply chains remain uninterrupted even during peak market demand.

5. Packaging & Regulatory Support

The final touch involves designing compliant, attractive packaging. Partners like CSK Biotech often provide value-added services such as free packaging design, alongside guidance on complex regulatory landscapes, ensuring your product is ready for shelves in the US, Europe, and beyond.

Manufacturing Models Demystified: OEM, ODM, and CDM

When engaging a manufacturer, it is crucial to understand the cooperation models available. Most advanced facilities offer flexible options to suit different business stages:

· Original Equipment Manufacturing (OEM): This is the classic custom supplement manufacturing model. You provide the formula and specifications; the manufacturer produces it precisely to your standards. It is ideal for established brands with proprietary recipes.

· Original Design Manufacturing (ODM): Perfect for rapid market entry, ODM allows brands to utilize the manufacturer's existing, market-tested formulas. These are often market-ready private label supplements that you can brand as your own, leveraging the manufacturer's R&D investment.

· Contract Design Manufacturing (CDM): A hybrid approach where the manufacturer designs a tailor-made product from scratch based on your broad concept.

CSK Biotech supports all three models—ODM, CDM, and OEM—providing the flexibility needed whether you are a startup looking for a turnkey solution or a legacy brand requiring precise replication.

Uncompromising Quality & Global Compliance

In the health industry, trust is the currency of success. This trust is built on a foundation of rigorous standards. A GMP certified supplement manufacturer adheres to the "Good Manufacturing Practices" enforced by the FDA. Specifically, under FDA 21 CFR Part 111, manufacturers must establish and follow strict procedures for manufacturing, packaging, labeling, and holding dietary supplements.

As noted by the FDA and legal experts, compliance with 21 CFR Part 111 is mandatory to ensure identity, purity, strength, and composition. Manufacturers must also navigate advertising regulations enforced by the Federal Trade Commission (FTC), which mandates that all health claims be truthful and substantiated by competent scientific evidence.

Top-tier makers go beyond the minimums. CSK Biotech, for example, holds multiple certifications including GMPC, FDA registration, HACCP (Hazard Analysis Critical Control Point), and ISO. These international certifications demonstrate a commitment to global quality management systems, ensuring traceability and safety that consumers worldwide can rely on.

Choosing Your Ideal Dietary Supplement Maker: An Evaluation Framework

Selecting a partner for 2026 involves more than comparing price quotes. Use this framework to evaluate potential partners:

· Experience & Specialization: Look for longevity and specific expertise. A company like CSK Biotech, with over 15 years of experience (founded in 2008), brings a wealth of problem-solving knowledge.

· Capacity & Scalability: Can they grow with you? A capacity of billions of units annually indicates a robust infrastructure capable of handling large retail orders.

· R&D Capabilities: Do they offer true innovation? A partner should proactively suggest novel ingredients and delivery forms.

· Regulatory Acumen: Ensure they understand dietary supplement regulations in your target markets, including the US (FDA), Europe, and Asia.

· Value-Added Services: Look for partners who offer more, such as free packaging design or marketing support, which can significantly reduce your overhead.

The Future of Manufacturing: Trends Shaping 2026

The industry is evolving rapidly. Future-ready manufacturers are already adopting:

· Personalized Nutrition: Leveraging data to create bespoke supplement solutions.

· Sustainable Sourcing: Meeting the consumer demand for eco-friendly packaging and ethically sourced ingredients.

· Advanced Automation: Using AI and robotics to enhance precision in supplement production process steps.

Conclusion: Partnering for Prosperity

To lead in the competitive dietary supplement market of 2026, you need a manufacturing partner that offers more than just capacity—you need a partner committed to innovation, quality, and your long-term growth. By choosing a comprehensive CDMO like CSK Biotech, you gain access to high-tech R&D, massive production scalability, and unwavering regulatory compliance. In a market defined by trust and efficacy, the right maker is your greatest asset.

Frequently Asked Questions

What is the difference between a CMO and a CDMO in dietary supplement manufacturing?

A CMO (Contract Manufacturing Organization) primarily focuses on the production aspect based on client specs. A CDMO (Contract Development and Manufacturing Organization), like CSK Biotech, provides end-to-end solutions including R&D, formulation, pilot testing, and regulatory support alongside manufacturing.

What key certifications should I look for in a reputable dietary supplement maker?

You should prioritize a GMP certified supplement manufacturer compliant with FDA 21 CFR Part 111. Additional certifications like ISO and HACCP are strong indicators of a robust quality management system and international safety standards.

How long does it typically take to develop and manufacture a new dietary supplement?

Timelines vary by complexity. Simple private label products might take a few months, while complex custom formulations requiring R&D and stability testing can take 6-12 months. A CDMO can often streamline this process through integrated services.

What are the common cooperation models offered by advanced manufacturers?

The main models are OEM (producing your specific formula), ODM (using the manufacturer's developed formulas for private label), and CDM (designing a new product from scratch). CSK Biotech offers all three to accommodate different brand needs.

Can dietary supplement makers assist with product formulation?

Yes, high-tech CDMOs specialize in supplement formulation services. They assist with ingredient selection, dosage optimization, and creating effective delivery systems for capsules, tablets, gummies, and more.

What is the typical annual production capacity of a leading manufacturer?

Leading facilities have massive scale. For example, CSK Biotech features an annual capacity exceeding 4.5 billion softgels and 1.5 billion tablets, ensuring they can meet the demands of global brands.

References

· FDA: Dietary Supplement Current Good Manufacturing Practices (cGMPs)

· P&S Intelligence: Dietary Supplements Market Size & Growth Report, 2030

· Federal Trade Commission: Dietary Supplements - An Advertising Guide for Industry

Latest Popular Articles

Discover expert tips from CSK Biotech, one of the top dietary supplements manufacturers, on handling international shipping and compliance for supplements. Ensure smooth global distribution with our comprehensive guide to regulations, packaging, and documentation. Stay compliant and competitive worldwide.

FAQ

文章

How does the cooperation process work?

Our standard cooperation process includes:

-

1.Product consultation and requirement confirmation

-

2.Formula development or review

-

3.Sample production (if required)

-

4.Order confirmation and mass production

-

5.Quality inspection and packaging

-

6.Delivery

This structured process ensures efficiency and transparency.

What quality control measures do you have?

Our quality control system includes:

-

· Raw material inspection and verification

-

· In-process quality monitoring

-

· Finished product testing

-

· Batch record management and traceability

Quality and compliance are integrated into every stage of our manufacturing process.

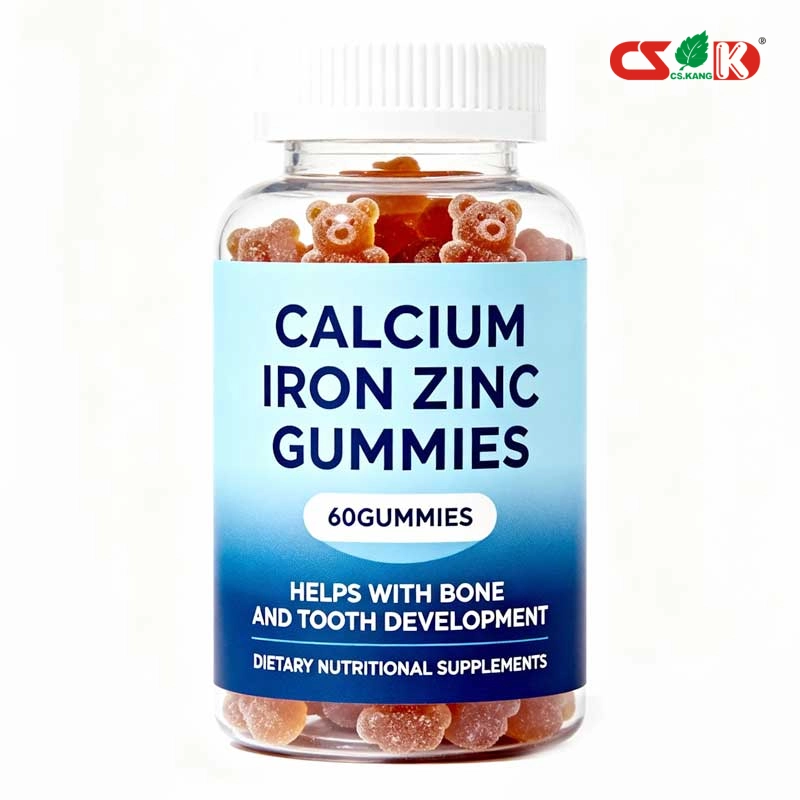

What types of dosage forms does CSK Biotech manufacture?

We offer a full range of supplement dosage forms, including:

-

· Softgel capsules

-

· Hard capsules

-

· Tablets

-

· Powder supplements

-

· Gummy supplements

-

· Liquid supplements (drops, syrups, oral liquids)

This allows our clients to build a complete and diversified product line with one reliable manufacturing partner.

Why choose CSK Biotech as your manufacturing partner?

Clients choose CSK Biotech because we offer:

-

· Comprehensive dosage form capabilities

-

· Strong customization and R&D support

-

· GMP-compliant manufacturing

-

· Reliable quality and stable supply

-

· One-stop OEM/ODM solutions

Who is CSK Biotech?

CSK Biotech is a professional biotechnology company specializing in OEM/ODM contract manufacturing of dietary supplements. We provide customized production services for softgel capsules, hard capsules, tablets, powders, gummies, and liquid supplements, supporting global brands from formulation to finished products.

Are your manufacturing facilities GMP certified?

Yes. CSK Biotech operates under GMP (Good Manufacturing Practices) standards. Our production facilities follow strict quality · · · management systems to ensure:

-

· Product safety

-

· Batch consistency

-

· Full traceability of raw materials and finished products

Related Products

Explore our range of complementary dietary supplement products designed to meet diverse formulation and market needs. Each item is developed and manufactured with the same high-quality standards and expertise that define our dietary supplement contract manufacturing services, helping brands expand their product offerings efficiently and reliably.

Request a Quote for Dietary Supplement Contract Manufacturing

If you need CDMO services for health foods, nutritional supplements, or cosmetics, our team of experts is ready to provide you with customized solutions and quotes.

manufactoryinchina

CSK Biotech Dietary Supplements