Common Quality Issues in Softgel Capsules: What Brands and Manufacturers Should Know

Softgel capsules are a widely used dosage form in the dietary supplement industry due to their versatility and consumer-friendly format. However, like all encapsulated products, softgels require careful control during formulation, manufacturing, packaging, and storage to maintain consistent quality.

Understanding common quality issues in softgel capsules helps brand owners, importers, and distributors make informed decisions when working with a contract manufacturer such as CSK Biotech.

Overview of Softgel Capsule Quality Management

Quality in softgel capsules refers to physical integrity, appearance, consistency, and stability, rather than any functional or health-related outcome. Quality standards are defined by internal specifications, Good Manufacturing Practice (GMP) requirements, and applicable food supplement regulations in different markets.

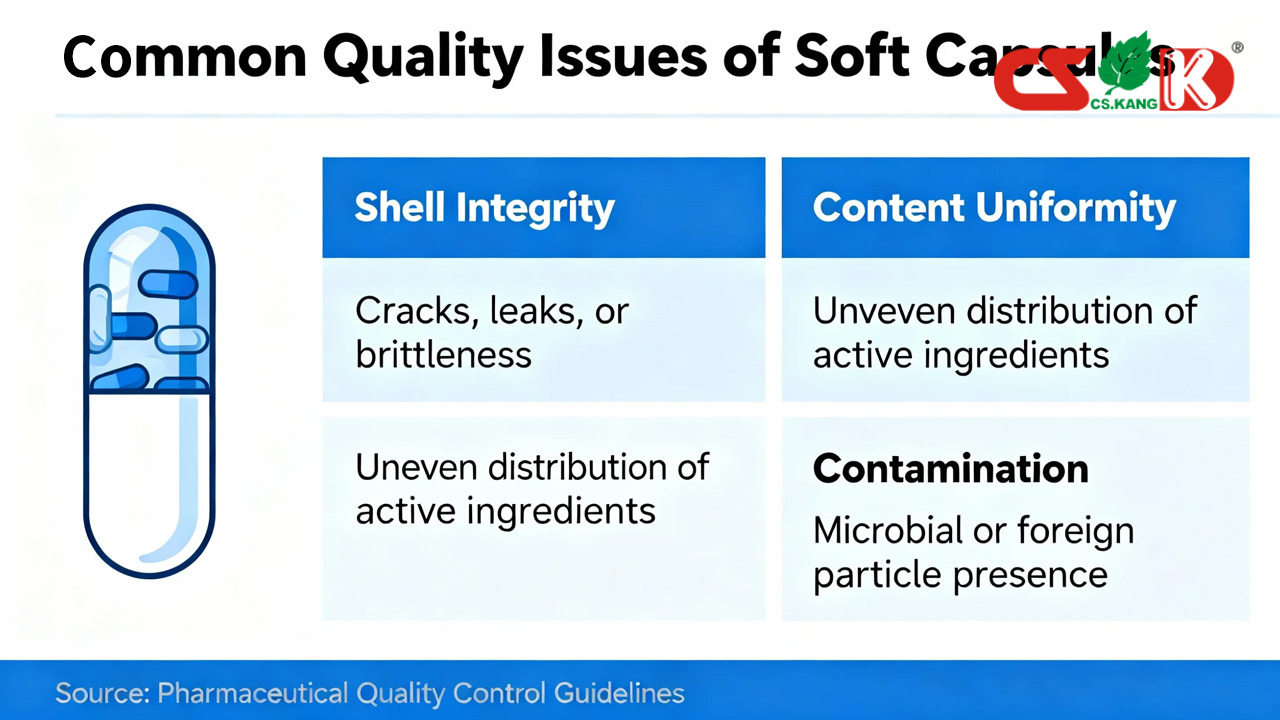

Common Quality Issues in Softgel Capsules

1. Leakage

Leakage occurs when the capsule shell fails to fully contain the fill material. This may result from:

-

Incompatible fill formulations

-

Improper sealing during encapsulation

-

Shell thickness inconsistencies

Leakage affects product appearance and packaging integrity and must be controlled through formulation compatibility testing and process validation.

2. Softening or Hardening of Capsules

Changes in capsule texture can occur due to moisture migration between the shell and fill material or exposure to unsuitable environmental conditions. Both excessive softening and hardening can impact handling and consumer perception.

3. Capsule Deformation or Stickiness

Softgel capsules may stick together or deform if exposed to elevated temperature or humidity during storage or transport. This issue is often linked to:

-

Inadequate environmental controls

-

Packaging with insufficient moisture barriers

4. Shell Cracking or Brittleness

Brittle shells or surface cracking can result from low moisture content, unsuitable plasticizer ratios, or extended exposure to dry conditions. Shell formulation and controlled drying processes are critical to minimizing this risk.

5. Color Variation

Minor color differences between batches may occur due to variations in raw materials or processing conditions. While color variation does not necessarily indicate a safety issue, it should be managed through standardized raw material specifications and batch controls.

6. Air Bubbles or Surface Imperfections

Trapped air or uneven shell surfaces can affect the visual quality of softgel capsules. These issues are typically related to encapsulation parameters and require regular equipment calibration and in-process inspection.

7. Odor or Sensory Changes

Changes in odor may occur over time if the fill material interacts with environmental factors such as oxygen or light. Proper formulation design and protective packaging help reduce the likelihood of such changes.

Factors Contributing to Quality Issues

Several factors can influence the occurrence of quality issues in softgel capsules:

-

Raw material variability

-

Formulation incompatibility

-

Environmental conditions during manufacturing

-

Packaging material selection

-

Storage and transportation environments

Managing these factors requires a structured quality management system.

Quality Control and Preventive Measures

At CSK Biotech, softgel capsule production is supported by:

-

GMP-compliant manufacturing environments

-

Defined in-process quality checks

-

Controlled temperature and humidity conditions

-

Stability planning and packaging compatibility assessments

These measures are designed to help reduce the likelihood of quality deviations throughout the product lifecycle.

Regulatory Considerations for Global Markets

Softgel capsule quality must align with dietary supplement and food regulations in key markets, including:

-

United States (FDA dietary supplement requirements)

-

European Union (Food Supplements Directive)

-

Germany (LFGB regulations)

-

China (applicable food and health product standards)

All quality-related information must be factual, documented, and free from misleading claims.

Conclusion

Softgel capsules offer flexibility in dietary supplement manufacturing, but maintaining consistent quality requires attention to formulation, processing, packaging, and storage. By understanding common quality issues and implementing appropriate controls, brands can better manage product consistency and compliance.

Working with an experienced manufacturer such as CSK Biotech supports the development of softgel capsule products that meet international quality expectations while remaining fully compliant with regulatory requirements.

Latest Popular Articles

Discover expert tips from CSK Biotech, one of the top dietary supplements manufacturers, on handling international shipping and compliance for supplements. Ensure smooth global distribution with our comprehensive guide to regulations, packaging, and documentation. Stay compliant and competitive worldwide.

FAQ

文章

Do you accept international orders?

Yes. CSK Biotech works with global clients and has experience supporting brands in:

-

· North America

-

· Europe

-

· Asia-Pacific

-

· Middle East and other regions

We are familiar with international cooperation processes and export requirements.

Does CSK Biotech provide OEM and ODM services?

Yes. CSK Biotech provides both OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services.

-

OEM: Manufacturing based on your existing formula and specifications

-

ODM: Full product development including formulation, dosage form design, and production

Our R&D team works closely with clients to turn concepts into market-ready products.

What types of dosage forms does CSK Biotech manufacture?

We offer a full range of supplement dosage forms, including:

-

· Softgel capsules

-

· Hard capsules

-

· Tablets

-

· Powder supplements

-

· Gummy supplements

-

· Liquid supplements (drops, syrups, oral liquids)

This allows our clients to build a complete and diversified product line with one reliable manufacturing partner.

How long does production usually take?

Production timelines vary depending on:

-

· Dosage form

-

· Formula complexity

-

· Order quantity

-

· Packaging requirements

Generally, production takes several weeks after formula confirmation and raw material preparation.

Are your manufacturing facilities GMP certified?

Yes. CSK Biotech operates under GMP (Good Manufacturing Practices) standards. Our production facilities follow strict quality · · · management systems to ensure:

-

· Product safety

-

· Batch consistency

-

· Full traceability of raw materials and finished products

What is your minimum order quantity (MOQ)?

MOQ depends on the dosage form, formula complexity, and packaging requirements. CSK Biotech offers flexible MOQs to support:

-

· Start-up brands

-

· New product launches

-

· Large-scale production orders

Please contact us for specific MOQ details.

Related Products

Explore our range of complementary dietary supplement products designed to meet diverse formulation and market needs. Each item is developed and manufactured with the same high-quality standards and expertise that define our dietary supplement contract manufacturing services, helping brands expand their product offerings efficiently and reliably.

Request a Quote for Dietary Supplement Contract Manufacturing

If you need CDMO services for health foods, nutritional supplements, or cosmetics, our team of experts is ready to provide you with customized solutions and quotes.

manufactoryinchina

CSK Biotech Dietary Supplements